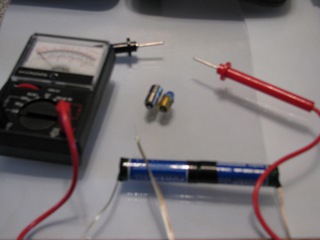

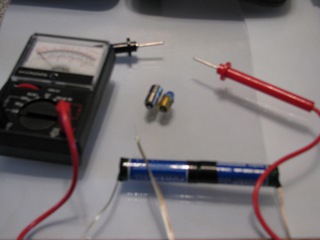

Received the LED replacement for the microscope's old, presumed tungsten, bulb. It's the silver-color bulb in the left-center of this image:

So why light?!? That's the LED, installed in the microscope. The batteries are in place. I confirmed I have power at the bulb contacts, and at the bulb. It's the same batteries, the same LED -- the only difference is the wires. Instead of the test leads, power's through the wires in the microscope. And those are working, because I have power at the contacts.

I just don't understand it.

I wanted to test the bulb before I installed it. No point in fitting it to the 'scope if the AA batteries won't power it. I don't have a power-source. So I scrounged some speaker-wire, taped the AA's together, and taped the speaker-wire onto the ends of the "battery pack." The voltmeter confirmed I had 3V power at the end of my test leads. Just for giggles, I applied the leads to the old blue bulb. As I very much expected, the old bulb didn't light. (Which is good -- now Nicole won't kill me for purchasing an unnecessary replacement LED.)

When I touched the leads to the LED, it lit. Huzzah! I have a working bulb, that can be powered by the 2 AA batteries that fit into the microscope's base.

When I touched the leads to the LED, it lit. Huzzah! I have a working bulb, that can be powered by the 2 AA batteries that fit into the microscope's base.

So why light?!? That's the LED, installed in the microscope. The batteries are in place. I confirmed I have power at the bulb contacts, and at the bulb. It's the same batteries, the same LED -- the only difference is the wires. Instead of the test leads, power's through the wires in the microscope. And those are working, because I have power at the contacts.

I just don't understand it.